London, November 28, 2025

3D printing technology is revolutionizing the boat manufacturing industry worldwide by enabling dramatically faster, cost-effective production while fostering innovative, sustainable designs. Leading companies and research centers reveal a transformation that cuts delivery times from years to weeks and automates most labor-intensive steps.

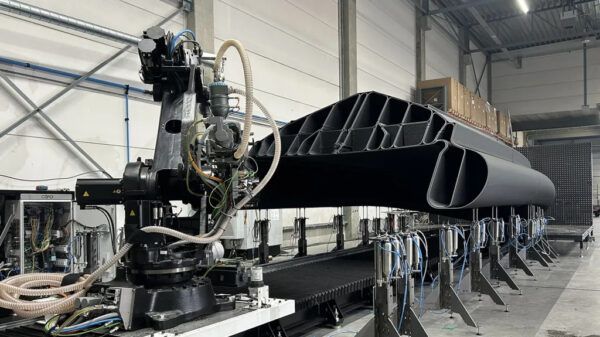

Rapid Production and Labor Efficiency

Advancements in large-scale additive manufacturing have enabled builders like Mr. Logtenberg’s team to print full boat hulls weekly, automating nearly 90% of the construction process. This marks a substantial acceleration compared to traditional boat building that often takes months to years. The automation also addresses skilled labor shortages and minimizes hazardous manual work, especially in processes like fiberglass lamination. Consequently, production costs decline as labor requirements fall, and manufacturers can meet demand more rapidly.

Design Freedom and Sustainability Benefits

3D printing liberates designers from conventional constraints such as expensive molds, permitting the realization of complex geometries, including double-curved surfaces and integrated components. The technology’s flexibility allows rapid design iteration and customization without costly retooling. Moreover, this manufacturing approach promotes sustainability through substantially reduced material waste and supports use of recyclable thermoplastic resins and recycled plastics. Many of these materials can be reprocessed, aligning boat manufacturing with global environmental imperatives.

Unmanned Vessels and Military Applications

The technology’s adaptability extends to unmanned surface vessels, which are increasingly valued for maritime operations. NATO special forces have experimented with printing adaptable drone boats within hours, enabling swift deployment tailored to mission requirements. The capacity for on-demand manufacturing of these remote vessels demonstrates the strategic advantage of 3D printing in defense and special operations contexts.

Scaling and Real-World Validation

Centers like CEAD’s Maritime Application Centre in the Netherlands and the University of Maine’s composites research hub have progressed from prototyping to producing full-scale, seaworthy vessels and boat molds. These facilities conduct rigorous real-world testing, confirming that 3D printed boats meet performance standards under operational conditions. Such validations underscore the readiness of additive manufacturing to scale commercially and function effectively beyond laboratory settings.

Market Outlook

Industry experts anticipate that within five years, 3D printed boats, especially in sectors such as high-speed workboats and recreational crafts, will dominate market segments. This forecast reflects the compounded advantages of reduced lead times, lowered costs, enhanced design capabilities, and sustainability credentials. As the maritime sector embraces this technological shift, 3D printing is set to redefine how boats are designed, constructed, and deployed globally, driving a new era of innovation and efficiency.